Full DIY Kit (6th Gen Bronco)

You can try your hand at my “Plan B” design; a kit where the primary bracket is assembled from 6 individual plates instead of 2 larger bent brackets.

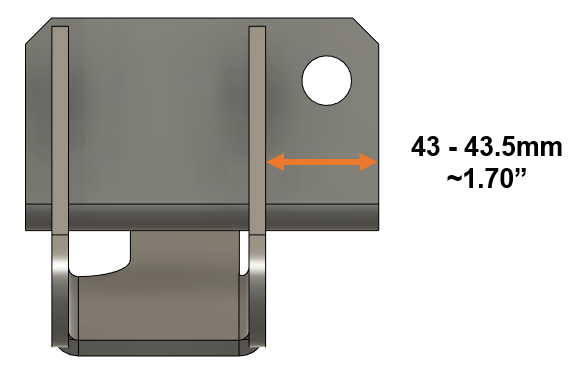

This design is trickier to orient and certainly has more room for error, both in dimensional accuracy as well as overall strength. If the templates are copied exactly, the assembly can be fabricated correctly and robustly. This kit is designed to lower the differential by 20mm at the axle center, allowing for nearly 12% reduction in max CV angle without exceeding the OEM CV plunge travel.

Each template includes the exact hole centers, as well as the hole size in mm. Also, you will find on certain parts simple instructions like what edge to radius (sander/grinder) or where to place a bend (front flange only). I recommend welding every joint/corner inside and out, there is adequate clearance to radius the interior corners of the frame facing bracket.

All plates are intended to be 1/4” steel. All spacers are intended to be 1/2” steel.

Included:

-3D printed templates for the 6 parts of the primary bracket

-3D printed templates for the rear and passenger spacers

-3D printed gauges for fabrication: 90° square, individual diff bolt spacer (to clamp between flanges), primary diff bracket alignment gauge

Optional:

-Necessary hardware for install

This kit (once completed) is entirely bolt on, but it will require modification of the OEM skid plate and may require modification of other aftermarket components as well. For more information to aid in the fabrication install, please check out my video (here), and my forum post (here).

You can try your hand at my “Plan B” design; a kit where the primary bracket is assembled from 6 individual plates instead of 2 larger bent brackets.

This design is trickier to orient and certainly has more room for error, both in dimensional accuracy as well as overall strength. If the templates are copied exactly, the assembly can be fabricated correctly and robustly. This kit is designed to lower the differential by 20mm at the axle center, allowing for nearly 12% reduction in max CV angle without exceeding the OEM CV plunge travel.

Each template includes the exact hole centers, as well as the hole size in mm. Also, you will find on certain parts simple instructions like what edge to radius (sander/grinder) or where to place a bend (front flange only). I recommend welding every joint/corner inside and out, there is adequate clearance to radius the interior corners of the frame facing bracket.

All plates are intended to be 1/4” steel. All spacers are intended to be 1/2” steel.

Included:

-3D printed templates for the 6 parts of the primary bracket

-3D printed templates for the rear and passenger spacers

-3D printed gauges for fabrication: 90° square, individual diff bolt spacer (to clamp between flanges), primary diff bracket alignment gauge

Optional:

-Necessary hardware for install

This kit (once completed) is entirely bolt on, but it will require modification of the OEM skid plate and may require modification of other aftermarket components as well. For more information to aid in the fabrication install, please check out my video (here), and my forum post (here).

You can try your hand at my “Plan B” design; a kit where the primary bracket is assembled from 6 individual plates instead of 2 larger bent brackets.

This design is trickier to orient and certainly has more room for error, both in dimensional accuracy as well as overall strength. If the templates are copied exactly, the assembly can be fabricated correctly and robustly. This kit is designed to lower the differential by 20mm at the axle center, allowing for nearly 12% reduction in max CV angle without exceeding the OEM CV plunge travel.

Each template includes the exact hole centers, as well as the hole size in mm. Also, you will find on certain parts simple instructions like what edge to radius (sander/grinder) or where to place a bend (front flange only). I recommend welding every joint/corner inside and out, there is adequate clearance to radius the interior corners of the frame facing bracket.

All plates are intended to be 1/4” steel. All spacers are intended to be 1/2” steel.

Included:

-3D printed templates for the 6 parts of the primary bracket

-3D printed templates for the rear and passenger spacers

-3D printed gauges for fabrication: 90° square, individual diff bolt spacer (to clamp between flanges), primary diff bracket alignment gauge

Optional:

-Necessary hardware for install

This kit (once completed) is entirely bolt on, but it will require modification of the OEM skid plate and may require modification of other aftermarket components as well. For more information to aid in the fabrication install, please check out my video (here), and my forum post (here).